PCB Process Capability

| No. | Project | Technical indicators |

| 1 | Layer | 1-60(layer) |

| 2 | Maximum processing area | 545 x 622 mm |

| 3 | Minimumboardthickness | 4(layer)0.40mm |

| 6(layer) 0.60mm | ||

| 8(layer) 0.8mm | ||

| 10(layer)1.0mm | ||

| 4 | Minimum line width | 0.0762mm |

| 5 | Minimum spacing | 0.0762mm |

| 6 | Minimum mechanical aperture | 0.15mm |

| 7 | Hole wall copper thickness | 0.015mm |

| 8 | Metallized aperture tolerance | ±0.05mm |

| 9 | Non-metallized aperture tolerance | ±0.025mm |

| 10 | Hole tolerance | ±0.05mm |

| 11 | Dimensional tolerance | ±0.076mm |

| 12 | Minimum solder bridge | 0.08mm |

| 13 | Insulation resistance | 1E+12Ω(normal) |

| 14 | Plate thickness ratio | 1:10 |

| 15 | Thermal shock | 288 ℃(4 times in 10 seconds) |

| 16 | Distorted and bent | ≤0.7% |

| 17 | Anti-electricity strength | >1.3KV/mm |

| 18 | Anti-stripping strength | 1.4N/mm |

| 19 | Solder resist hardness | ≥6H |

| 20 | Flame retardancy | 94V-0 |

| 21 | Impedance control | ±5% |

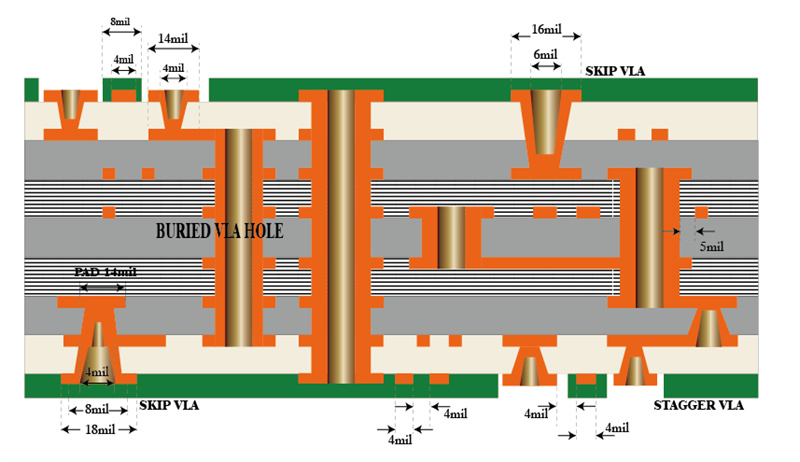

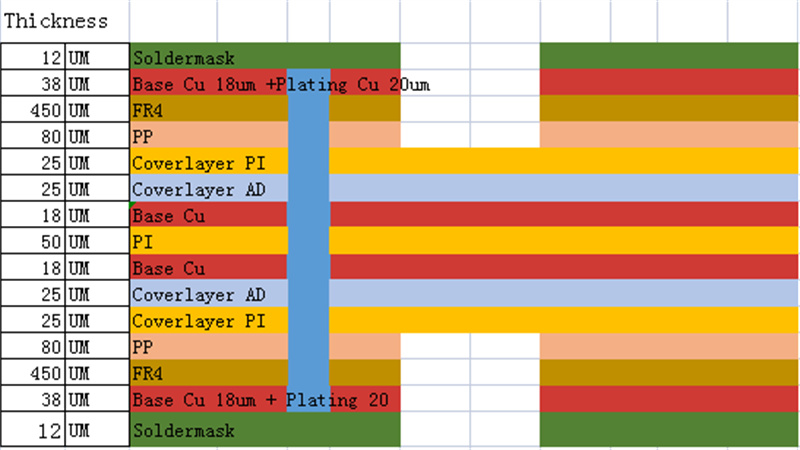

We do HDI Circuit Board with 15 years' experience with our professionalism

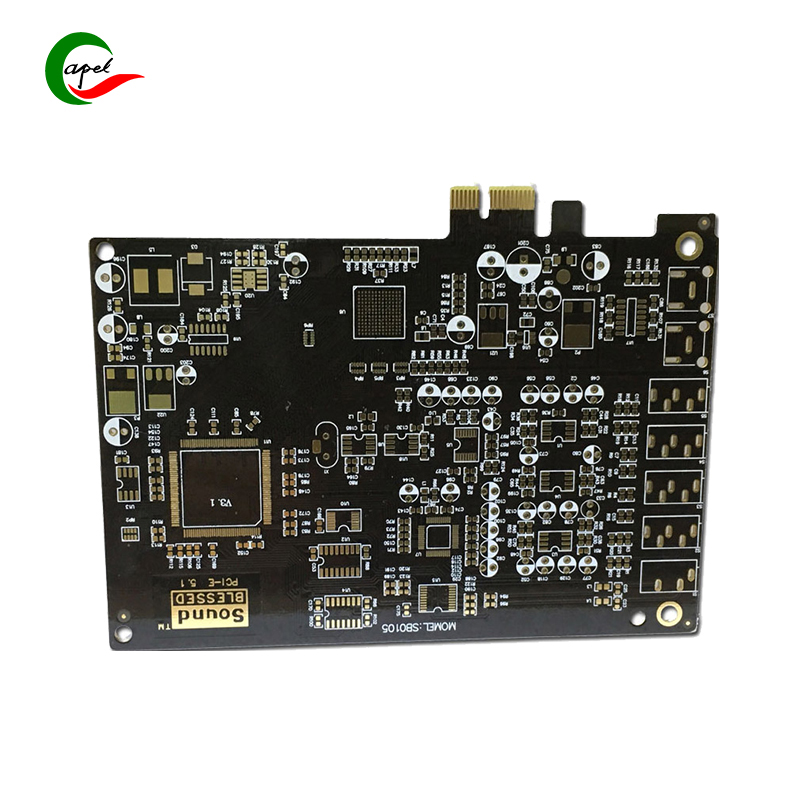

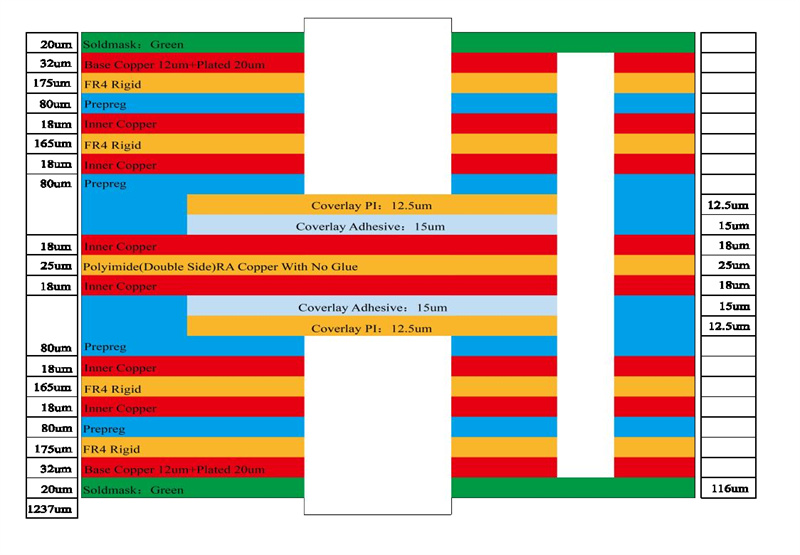

8 layer HDI PCBs

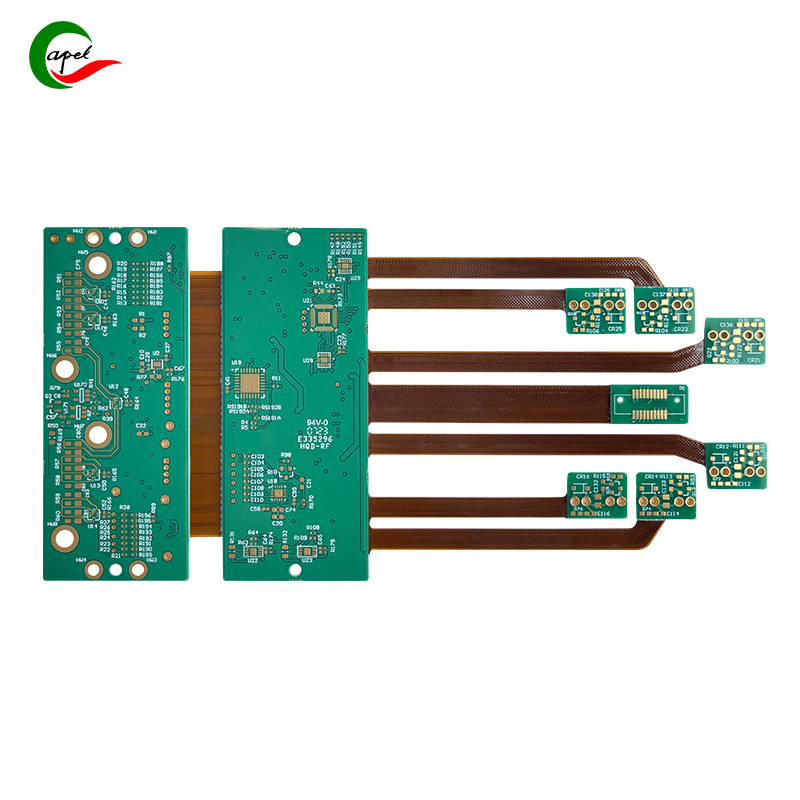

4 layer Flex-Rigid Boards

8 layer Rigid-Flex PCBs

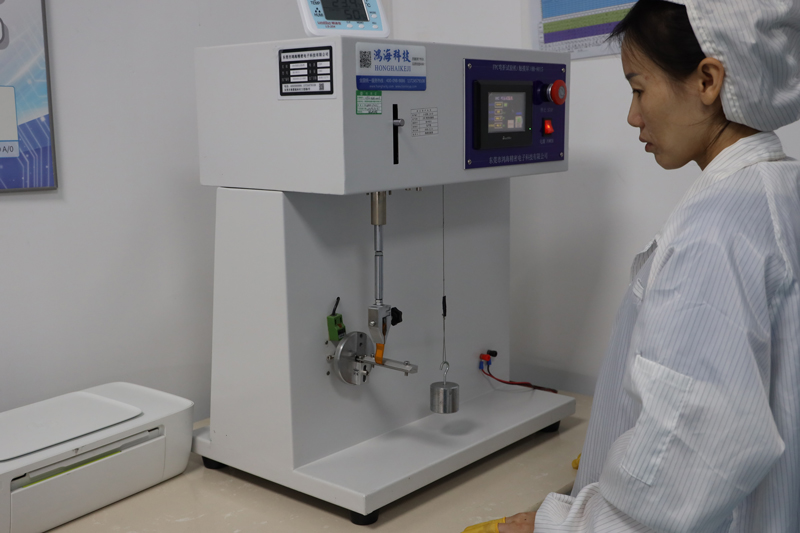

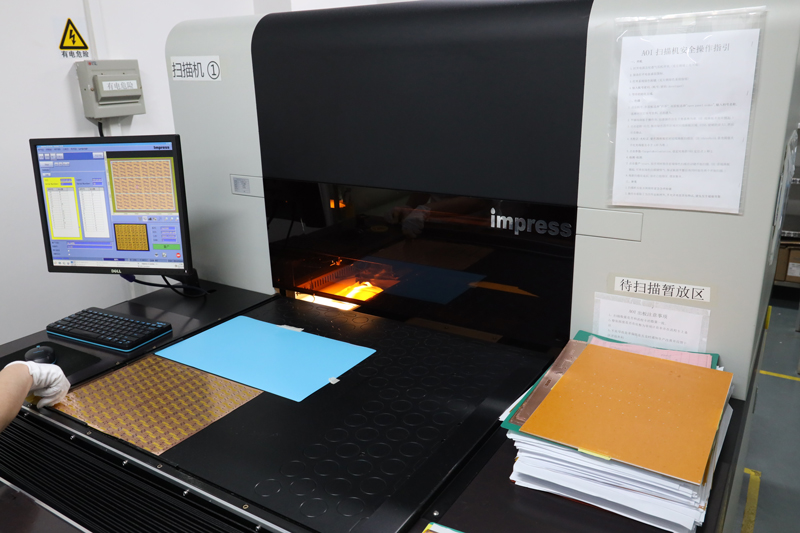

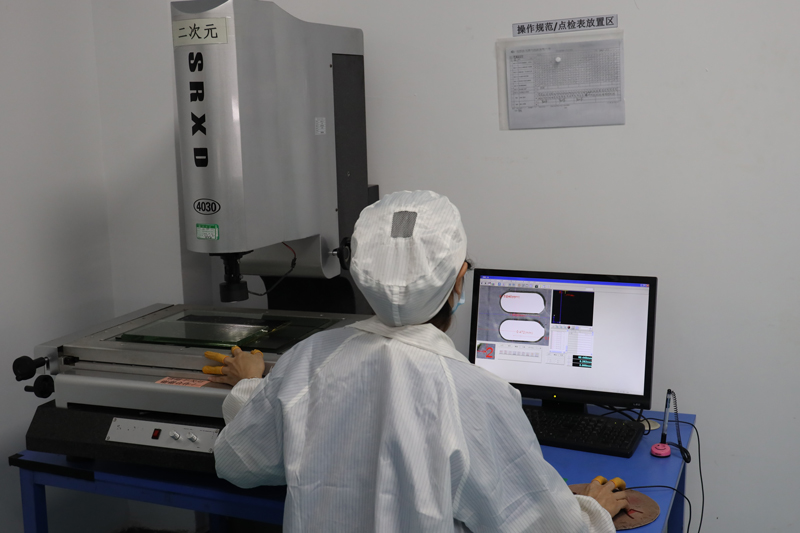

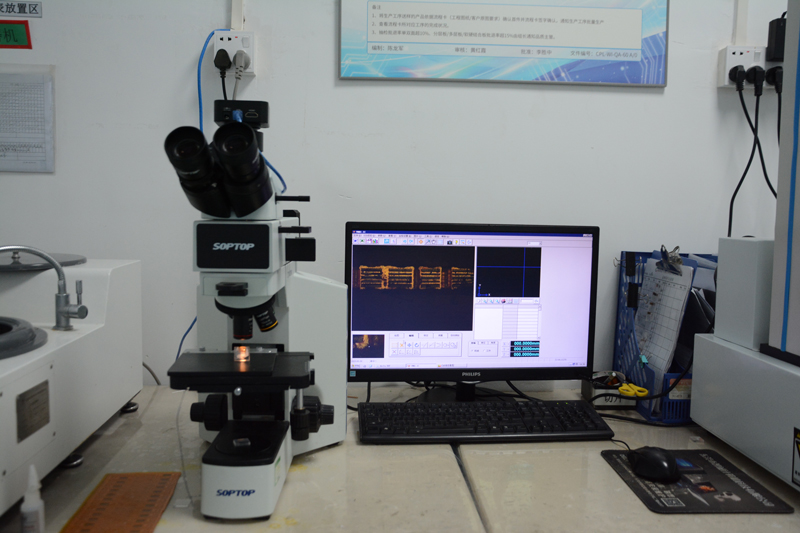

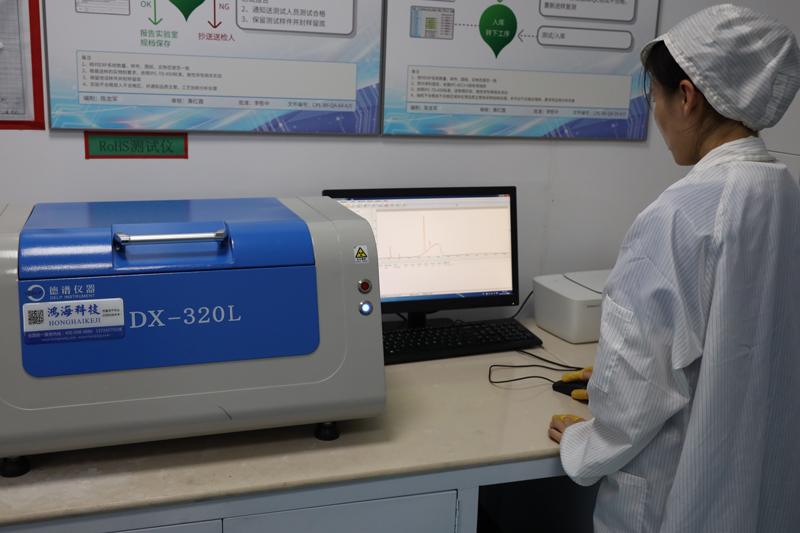

Testing and Inspection Equipment

How to choose Single-sided fr4 PCB manufacturer?

. Provide technical support Pre-sales and after-sales; . Custom up to 40 layers, 1-2days Quick turn reliable prototyping, Component procurement, SMT Assembly; . Caters to both Medical Device, Industrial Control, Automotive, Aviation, Consumer Electronics, IOT, UAV, Communications etc.. . Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.

Our HDI Circuit Board Service

1. Quality and reliability: - Look for a manufacturer with a solid reputation for producing high-quality PCBs. View customer reviews, testimonials, and references (where available). - Ensure manufacturers follow industry standards and certifications (eg ISO 9001) to ensure a consistent quality control process. - Consider their track record of delivering reliable products on time and meeting customer specifications. 2. Manufacturing capacity and technology: - Assess their manufacturing capabilities, including their equipment, facilities and technical expertise. - Check that they have the necessary capabilities to handle your specific PCB requirements such as size, thickness and material specifications. - Ask about their ability to handle various finish options and solder mask colors.3. Design support and service: - Evaluate whether the manufacturer offers design support or engineering services to help you optimize your PCB design. - Check their ability to provide design reviews or provide design for manufacturability (DFM) analysis for early detection of potential issues. - Consider their ability to handle design modifications or revisions throughout the manufacturing process. 4. Pricing and Quotation: - Request quotes from multiple manufacturers and compare their prices. - Beware of low prices as this may indicate quality issues or insufficient manufacturing capacity. - Seek transparency on pricing, including any additional costs for tooling, setup, or expedited production. 5. Manufacturing lead time: - Determine typical production and delivery lead times for manufacturers. - Find out about their manufacturing capabilities and whether they can meet your desired production schedule or any potential urgency. 6. Customer Support and Communication: - Assess the manufacturer's responsiveness and ability to address your inquiries, concerns or issues in a timely manner. - Consider their availability and willingness to provide support and information throughout the manufacturing process. - Find effective communication channels such as email, phone or live chat. 7. Additional services: - Determine if the manufacturer offers additional services such as PCB assembly, testing, or component sourcing (if required). - Evaluate the availability of value-added services such as design verification, functional testing or product packaging.