Capel Flexible PCB & Rigid-Flex PCB Process Capability

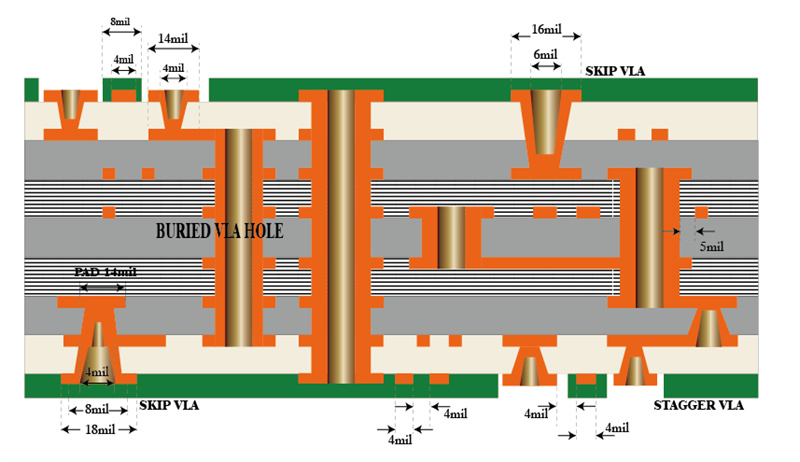

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB | Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm | Insulating Layer Thickness | 27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm | Tolerance of PTH Size | ±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP | Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance | ±10% |

| Tolerance of NPTH Size | ±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel manufactures customized high-precision Rigid Flexible Circuit Board / Flexible PCB / HDI PCB with 15 years of experience with our professionalism

8 layer HDI PCBs

2 Layers Double-sided Fpc Pcb

4-layers Rigid-Flex PCB

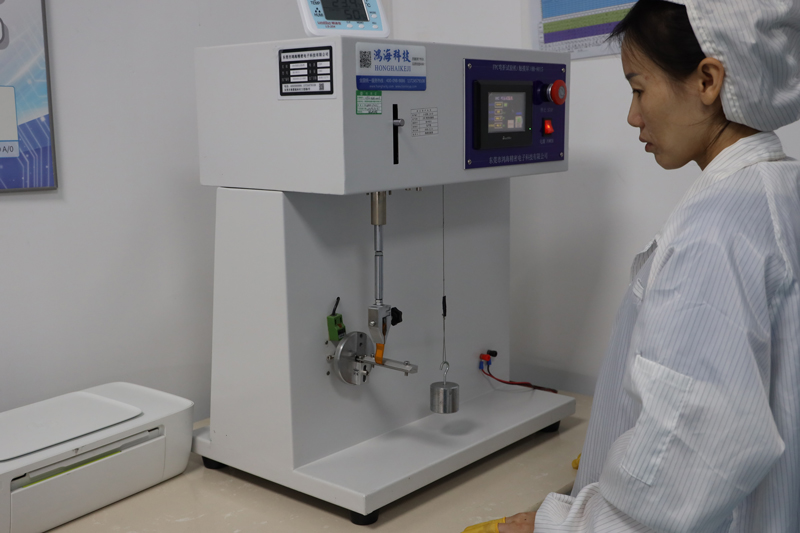

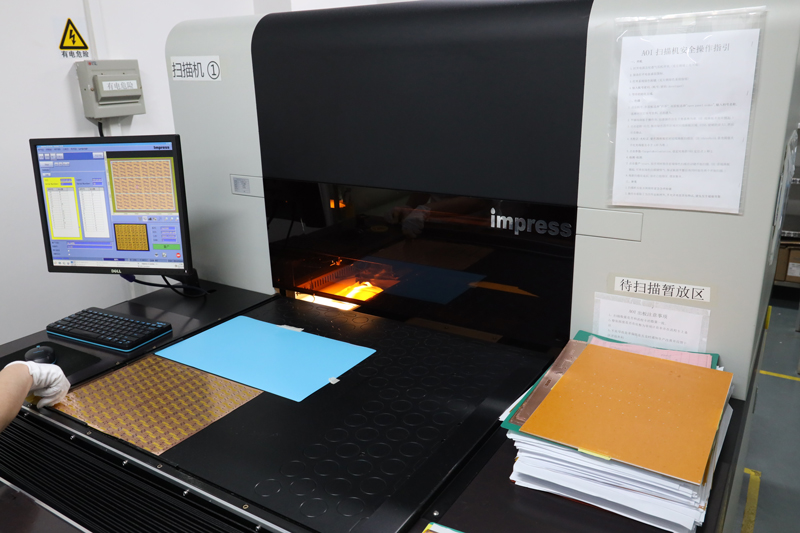

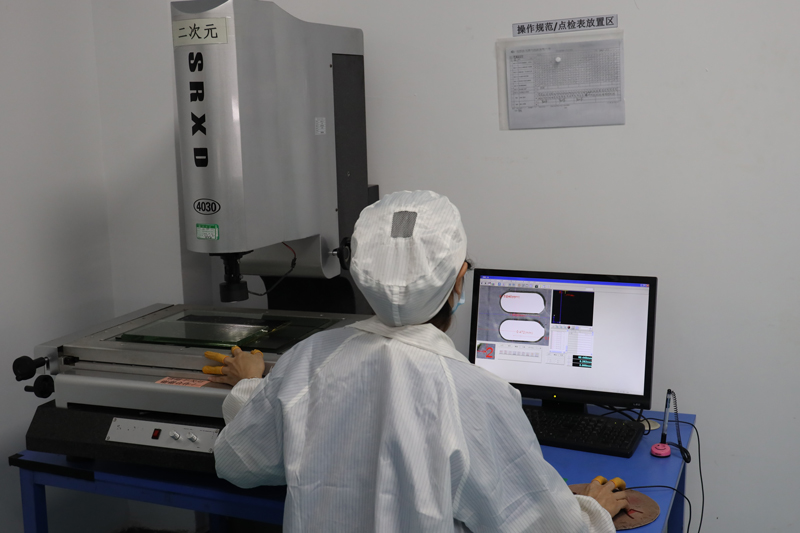

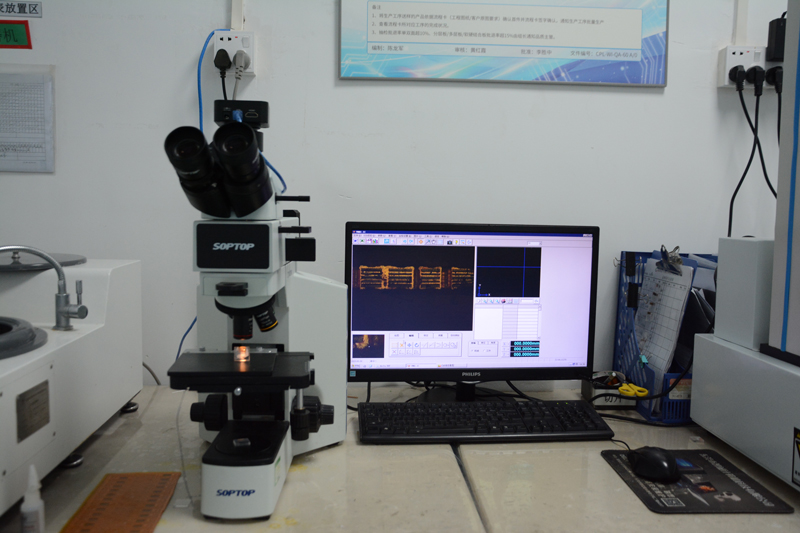

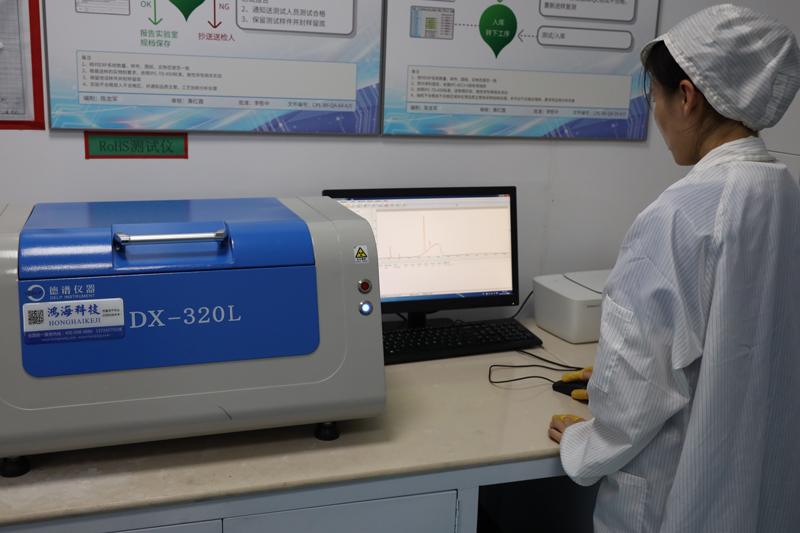

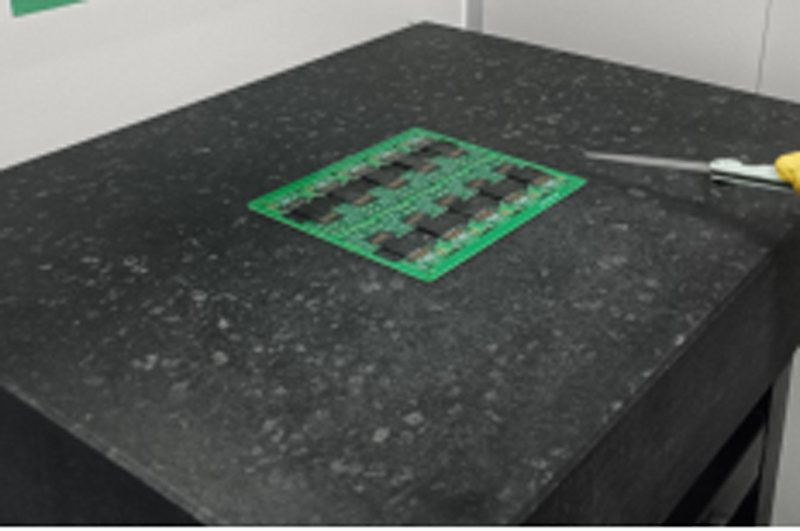

Testing and Inspection Equipment

How Capel's 2 Layer FPC Flexible PCB Automotive Boards New Energy Battery Flex Circuit Provides Reliability Solutions for Automotive New Energy Battery manufacturers

-Capel with 15 years of professional technical experience-- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity: FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month, PCB production capacity can reach 80000sqm per month, PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.

Capel provide customers customized PCB Service with 15 years of experience

Launched the perfect solution for automotive new energy batteries - 2-layer FPC flexible PCB Are you working in the automotive industry, with a particular focus on new energy battery technology? If so, we have the perfect product for you - 2-Layer FPC Flexible PCB. This innovative PCB is specifically designed for automotive new energy battery applications, providing unparalleled reliability, performance and flexibility. When it comes to car batteries, precision is key. That's why our 2-layer FPC flexible PCBs are designed to meet the most demanding requirements. With line width and line spacing of 0.1mm/0.1mm, you can be confident in the accuracy and consistency of your electrical connections. This ensures optimal power transfer and maximum efficiency from the battery. Additionally, a 0.3mm plate thickness enables a compact, lightweight battery design without compromising durability. The minimum aperture of 0.2mm ensures precise placement of components and enables seamless integration of various battery modules. One of the key features of our 2-layer FPC flexible PCB is the copper thickness of 35um. This high copper thickness ensures excellent electrical conductivity, reducing energy loss and improving the overall performance of the battery. Additionally, our boards are ENIG 2-3uin surface treated for superior corrosion resistance and a smooth surface for reliable solder joints. In order to further improve the reliability of 2-layer FPC flexible PCB, we use a special brown oxidation process. This process creates a protective layer on the surface of the circuit board, increasing its resistance to harsh environmental conditions such as temperature fluctuations, humidity and chemical exposure. Rest assured, your car battery will perform flawlessly no matter what conditions it encounters. Safety is always a top priority, especially in the automotive industry. Our 2-layer FPC flexible PCBs are designed with flame retardancy in mind and comply with strict 94V0 industry standards. This ensures that the circuit board will not fuel or spread a fire, minimizing potential hazards and ensuring maximum safety for new energy batteries. In terms of aesthetics, our 2-layer FPC flexible PCB uses resistance welding and comes in a bright yellow color. This eye-catching feature allows for easy identification and differentiation during production and assembly processes, streamlining your operations and increasing efficiency. Flexibility is another outstanding feature of our 2-layer FPC flexible PCBs. With hardness options such as nickel sheet, FR4 and foam, you can customize your PCB to meet specific design requirements. Whether you need flexibility to fit into tight spaces or rigidity for added stability, we have a solution for you. To sum up, our 2-layer FPC flexible PCB is the best choice for automotive new energy batteries. With their exceptional precision, reliability and flexibility, they are guaranteed to improve battery performance and safety. Believe in our superior products and use our expertise to stay ahead in the highly competitive automotive market. Choose our 2-layer FPC flexible PCBs and witness the changes they bring to your battery technology.