Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB | Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm | Insulating Layer Thickness | 27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm | Tolerance of PTH Size | ±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP | Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance | ±10% |

| Tolerance of NPTH Size | ±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Rigid Flexible Circuit Board with 15 years of experience with our professionalism

8 layer HDI PCBs

2 Layers Double-sided Fpc Pcb

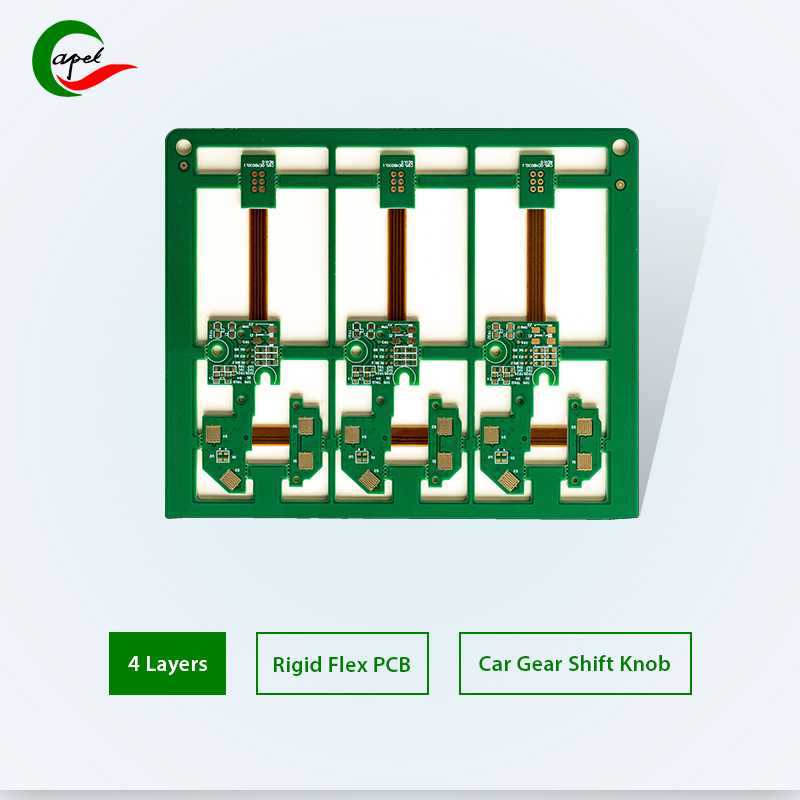

4-layers Rigid-Flex PCB

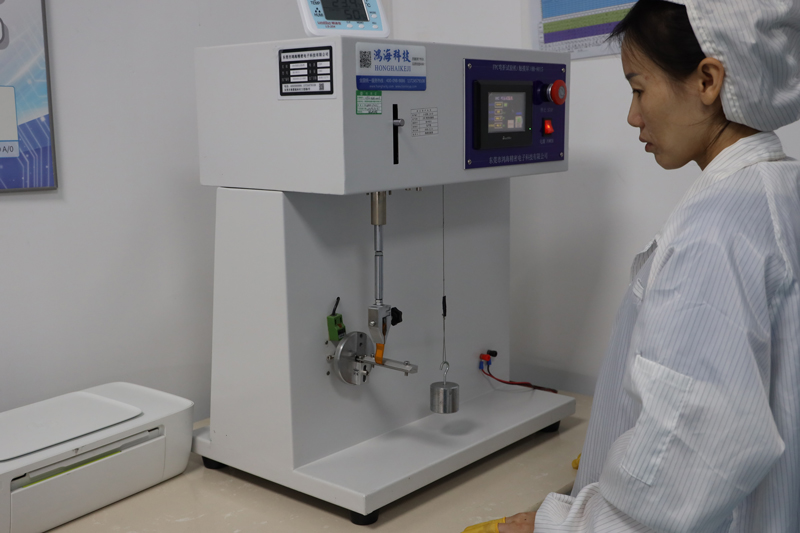

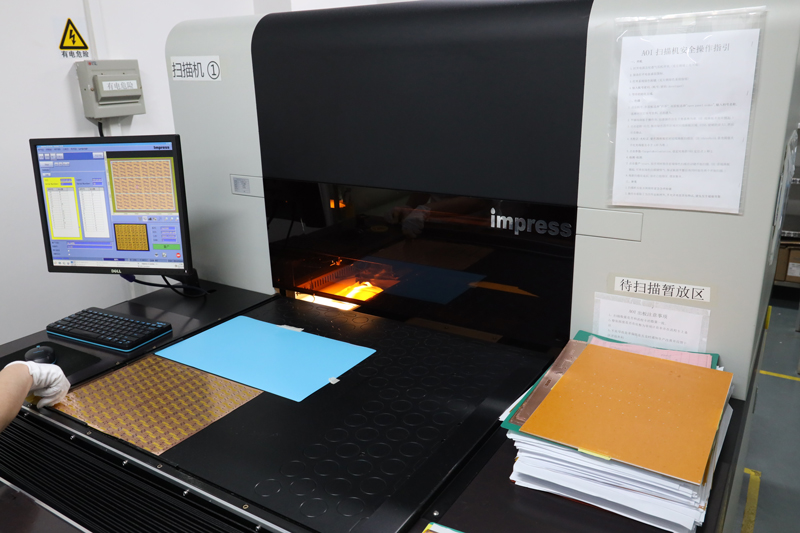

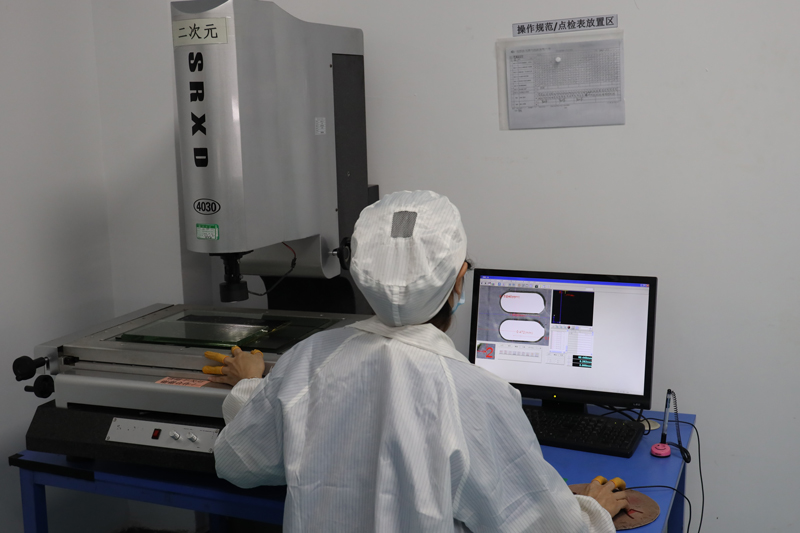

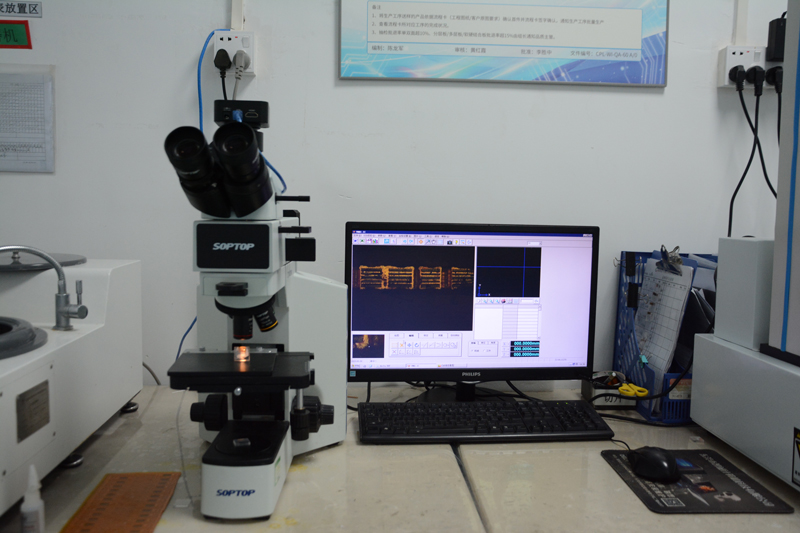

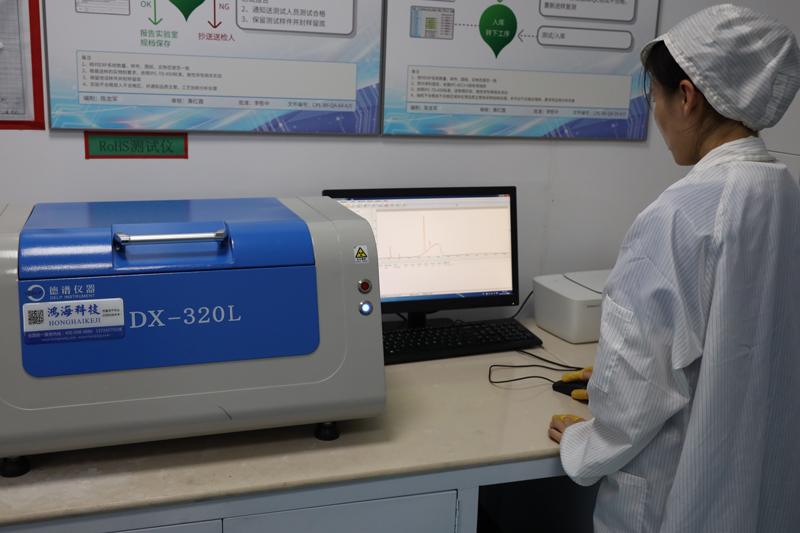

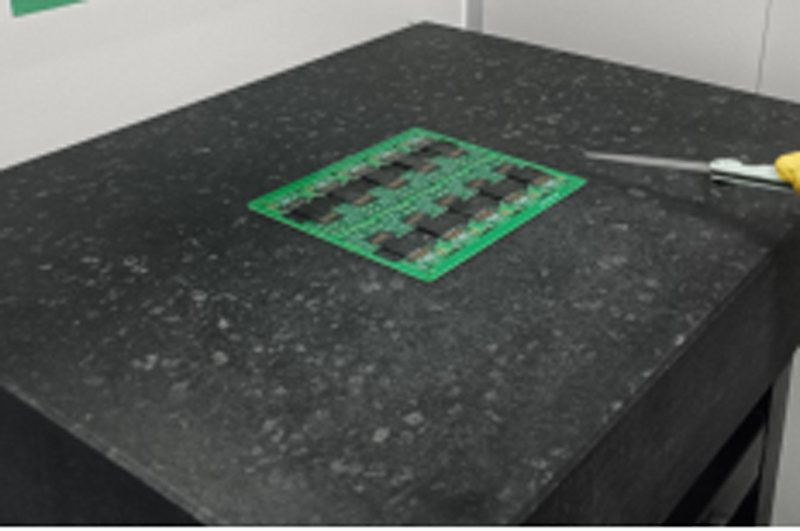

Testing and Inspection Equipment

How Capel's 10 Layer Rigid Flex PCB Stackup NiPdAu PCB Prototype Copper Thickness 18um 35um Provides Reliability Solutions for Our Customers

-Capel with 15 years of professional technical experience-- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity: FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month, PCB production capacity can reach 80000sqm per month, PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.

Capel customized Flex PCB/Rigid Flexible Boards Service with 15 years of experience

NiPdAu surface treatment improves reliability: NiPdAu (Nickel Palladium Gold) surface treatment is widely used in the PCB industry due to its excellent conductivity, corrosion resistance and durability. This surface treatment protects the underlying copper traces from oxidation and ensures reliable performance in a variety of environments. By providing a uniform and reliable surface for component soldering, the NiPdAu surface treatment imparts stability to the PCB, thereby extending its service life. Copper Thickness: Achieving the Right Balance: The thickness of copper in a PCB directly affects its conductivity and heat dissipation. For a 10-layer rigid-flex PCB stackup, maintaining proper copper thickness is critical. Typically, 18um copper thickness is suitable for inner layers to ensure efficient signal propagation. On the other hand, the 35um outer layer thickness facilitates better power distribution and dissipation. Successful prototyping: Before considering large-scale production, it is crucial to develop reliable prototypes. Prototyping allows engineers to verify the design, identify potential flaws and make necessary adjustments. When developing a 10-layer rigid-flex PCB stackup, prototyping becomes even more important due to the complexity involved. By working with experienced PCB manufacturers and leveraging state-of-the-art technology, prototypes can be efficiently manufactured, tested and optimized to achieve the required performance levels.