High-quality 8 Layer Flex Board PCB for Superior Performance

By:Admin

[City, State] – [Date] – [Company Name], a leading provider of innovative printed circuit board (PCB) solutions, has announced the release of a new 8 layer flex board PCB, designed to meet the demands of high-performance applications in various industries.

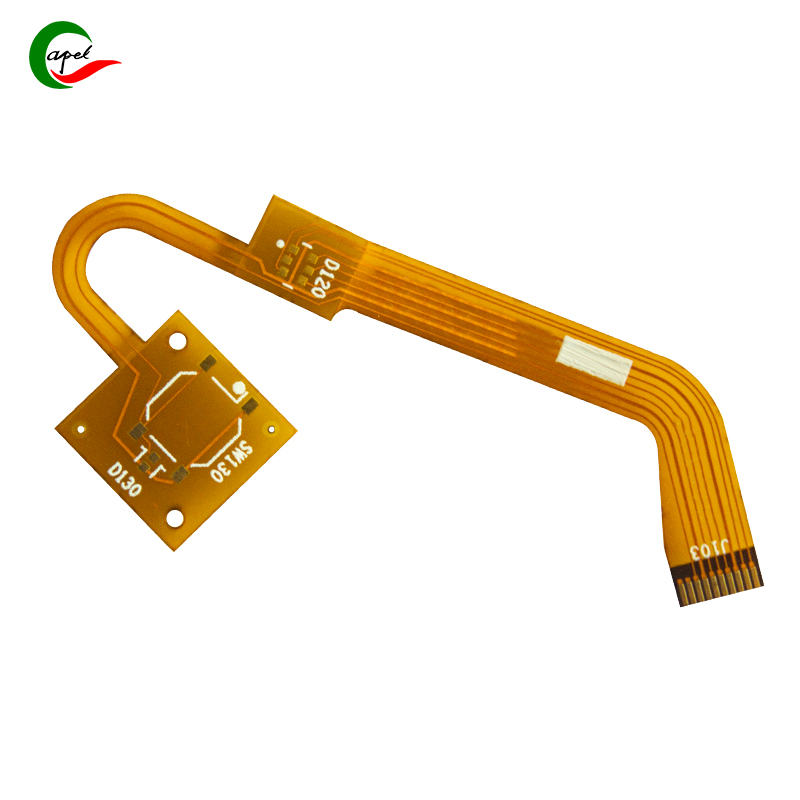

The new 8 layer flex board PCB offers a number of advanced features and capabilities, making it an ideal solution for applications that require high-density interconnects, superior signal integrity, and flexibility. The PCB is designed to accommodate complex circuitry and provides enhanced functionality for a wide range of applications, including telecommunications, medical devices, aerospace, and more.

“With the increasing demands for high-performance and compact electronic devices, we recognized the need for a PCB solution that offers advanced capabilities in terms of flexibility, signal integrity, and reliability,” said [Spokesperson Name], CEO of [Company Name]. “Our new 8 layer flex board PCB is the result of extensive research and development, and we are confident that it will meet the needs of our customers across various industries.”

The 8 layer flex board PCB is built using advanced materials and manufacturing processes to ensure superior performance and durability. It features a flexible design that allows for bending and folding, making it suitable for applications that require a high degree of flexibility. Additionally, the PCB offers excellent signal integrity, enabling high-speed data transmission and reliable operation in demanding environments.

One of the key highlights of the 8 layer flex board PCB is its high-density interconnect capability, which allows for the integration of complex circuitry within a compact form factor. This feature makes the PCB well-suited for space-constrained applications, where a high degree of functionality is required within a limited footprint.

[Company Name] is known for its commitment to innovation and quality, and the release of the new 8 layer flex board PCB is a testament to the company’s dedication to providing advanced PCB solutions to meet the evolving needs of the industry. With a focus on technological advancements and customer satisfaction, [Company Name] continues to push the boundaries of PCB design and manufacturing.

The launch of the 8 layer flex board PCB further solidifies [Company Name]’s position as a leading provider of innovative PCB solutions, catering to a diverse range of industries. By leveraging its expertise in PCB design and manufacturing, the company aims to address the growing demand for high-performance and reliable PCB solutions in today’s competitive marketplace.

“Our goal is to empower our customers with cutting-edge PCB solutions that enable them to achieve their design objectives and stay ahead of the competition,” added [Spokesperson Name]. “The launch of the 8 layer flex board PCB underscores our commitment to delivering the highest quality products and exceeding the expectations of our customers.”

With the release of the new 8 layer flex board PCB, [Company Name] is poised to set new benchmarks in PCB technology, offering a solution that combines advanced capabilities with flexibility and reliability. The company remains dedicated to driving innovation and meeting the evolving needs of the industry, positioning itself as a preferred partner for PCB solutions across various market segments.

For more information about [Company Name] and its range of advanced PCB solutions, visit [website URL] or contact [contact information].

About [Company Name]:

[Company Name] is a leading provider of innovative printed circuit board (PCB) solutions, offering a comprehensive range of products and services to meet the evolving needs of the industry. With a focus on advanced technology and customer satisfaction, the company is committed to delivering high-quality PCB solutions for a diverse range of applications. By leveraging its expertise and capabilities, [Company Name] aims to drive innovation and provide reliable PCB solutions tailored to the specific requirements of its customers.

Company News & Blog

How Circuit Boards are Manufactured and its Uses

Smt Circuit Board Company Introduces Cutting-Edge TechnologySmt Circuit Board, a leading manufacturer of high-quality printed circuit boards, is revolutionizing the industry with the introduction of their state-of-the-art production technology. The company, with its headquarters in (location), has been at the forefront of innovation for over a decade, and their latest technological advancement is set to further cement their position as a pioneer in the field.The new technology, which the company has developed in-house, promises to significantly enhance the efficiency and precision of the manufacturing process. Through the integration of advanced robotics and automated systems, Smt Circuit Board has been able to achieve unprecedented levels of accuracy and consistency in the production of their circuit boards. This breakthrough will not only enable the company to meet the growing demand for their products but also to exceed the expectations of their customers in terms of quality and reliability.In addition to improving the manufacturing process, Smt Circuit Board's new technology also has the potential to reduce production costs, making their products more competitive in the market. By streamlining operations and minimizing the margin for error, the company anticipates being able to offer their cutting-edge circuit boards at more competitive prices, thereby further increasing their appeal to existing and prospective customers."We are thrilled to announce the launch of our latest technological innovation," said the CEO of Smt Circuit Board. "We have always been committed to pushing the boundaries of what is possible in the world of printed circuit board manufacturing, and this new development is a testament to that commitment. We believe that this technology will not only benefit our company but also the entire industry as a whole, by setting a new standard for excellence and efficiency."The company's dedication to innovation and excellence is further reflected in their commitment to sustainability. Smt Circuit Board has made substantial investments in environmentally friendly production methods, and their new technology is no exception. By optimizing resource utilization and reducing waste, the company seeks to minimize their environmental footprint and contribute to a more sustainable future for the industry.Smt Circuit Board's cutting-edge technology has already garnered significant attention from industry insiders and experts, with many hailing it as a game-changer for the printed circuit board manufacturing sector. The company has already begun the process of integrating the new technology into their production facilities, and they expect to see tangible results in the near future."We are confident that this technology will position us as a leader in the industry and enable us to continue delivering superior products and services to our customers," said the CEO. "We are excited about the possibilities that this innovation opens up for us, and we look forward to the positive impact it will have on our business and the industry as a whole."As Smt Circuit Board prepares to roll out their groundbreaking new technology, the company is poised to reaffirm its position as a frontrunner in the printed circuit board manufacturing sector. With a track record of innovation, excellence, and customer satisfaction, Smt Circuit Board is set to continue leading the way in the industry for years to come.

The Importance of Pcb Substrate in Electronic Manufacturing

{Company Name}, a leading provider of electronic components and solutions, has recently unveiled a new and innovative PCB substrate that is set to revolutionize the electronics industry. The new substrate, which is a crucial component in the manufacturing of printed circuit boards (PCBs), is expected to offer enhanced performance and reliability to a wide range of electronic devices.The new PCB substrate is designed to address the increasing demand for advanced electronic components that can support higher frequencies and data transmission rates. With the proliferation of 5G technology and the Internet of Things (IoT), the need for high-performance PCB substrates has become more critical than ever. {Company Name}'s latest offering aims to meet this demand by providing a reliable and efficient solution for manufacturers of electronic devices.One of the key features of the new PCB substrate is its improved thermal performance. With the growing complexity and miniaturization of electronic devices, thermal management has become a major concern for manufacturers. The new substrate is designed to dissipate heat more effectively, allowing electronic components to operate at optimal temperatures and significantly reducing the risk of overheating.In addition to its thermal properties, the new PCB substrate also offers excellent electrical performance. With lower signal loss and impedance, the substrate enables high-speed data transmission with minimal interference, making it an ideal choice for applications that require high-frequency performance.{Company Name} has a strong track record of innovation and excellence in the field of electronic components. With a focus on research and development, the company has consistently delivered cutting-edge solutions that have set new benchmarks for performance and reliability. The introduction of the new PCB substrate is a testament to {Company Name}'s commitment to pushing the boundaries of electronic technology and delivering value to its customers.The new PCB substrate is expected to find applications in a wide range of industries, including telecommunications, automotive, aerospace, and consumer electronics. Its versatility and reliability make it suitable for use in various electronic devices, from smartphones and tablets to high-performance computing systems.{Company Name} has also emphasized the environmental sustainability of the new PCB substrate. As a responsible corporate citizen, the company has integrated eco-friendly materials and manufacturing processes into the production of the new substrate, ensuring that it meets the highest standards of environmental stewardship.The launch of the new PCB substrate is poised to strengthen {Company Name}'s position as a market leader in the electronic components industry. With its focus on innovation, performance, and sustainability, the company is well-positioned to meet the evolving needs of the electronics market and drive the advancement of technology.In conclusion, the introduction of the new PCB substrate by {Company Name} marks a significant milestone in the electronic components industry. With its advanced thermal and electrical performance, as well as its environmental sustainability, the substrate is poised to set new standards for reliability and efficiency in electronic devices. As the demand for high-performance electronic components continues to grow, {Company Name} remains at the forefront of innovation, delivering solutions that create value for its customers and contribute to the advancement of technology.

Ultimate Guide to Multilayer Rigid-Flex PCB - Everything You Need to Know

Multilayer Rigid-Flex PCB is a revolutionary technology that is changing the way electronic devices are designed and manufactured. This innovative technology is being developed by {company}, a leading provider of advanced PCB solutions. This new technology has the potential to completely transform the electronics industry, making products more efficient, reliable, and compact.Multilayer Rigid-Flex PCB is a combination of rigid and flexible PCBs, which allows for intricate designs that were previously thought to be impossible. This technology enables electronic devices to be more compact, durable, and efficient, making it ideal for a wide range of applications such as consumer electronics, automotive, aerospace, medical devices, and more.The {company} is at the forefront of developing and manufacturing Multilayer Rigid-Flex PCB technology. With their expertise in advanced PCB solutions, they have been able to create a cutting-edge technology that is revolutionizing the electronics industry. Their state-of-the-art facilities and team of highly skilled engineers and technicians have enabled them to push the boundaries of what is possible in PCB technology.One of the key features of Multilayer Rigid-Flex PCB is the ability to combine multiple PCBs into a single, compact unit. This allows for a significant reduction in the overall size of the electronic device, while also simplifying the manufacturing process. Additionally, the flexibility of the PCBs allows for more intricate designs and greater durability, making it more resistant to shocks, vibrations, and other environmental factors.In addition to size and durability, Multilayer Rigid-Flex PCB also offers improved reliability and performance. The rigid and flexible portions of the PCB are designed to work seamlessly together, resulting in better overall performance and efficiency. This is particularly important for electronic devices that are subject to harsh environmental conditions or high levels of vibration, such as those used in automotive or aerospace applications.Another key advantage of Multilayer Rigid-Flex PCB is the ability to reduce the number of interconnects and solder joints, which in turn reduces the risk of failure and improves overall reliability. This makes the technology ideal for critical applications such as medical devices, where reliability is of the utmost importance.The {company} has been at the forefront of developing and commercializing Multilayer Rigid-Flex PCB technology. With their extensive experience and expertise in advanced PCB solutions, they have been able to bring this cutting-edge technology to the market. This has opened up new possibilities for electronic devices, allowing for more compact, durable, and efficient designs.As the demand for smaller, more reliable, and efficient electronic devices continues to grow, the development of Multilayer Rigid-Flex PCB technology has never been more important. The {company} is committed to continuing to push the boundaries of what is possible in PCB technology, and they are dedicated to bringing this revolutionary technology to a wide range of industries.In conclusion, Multilayer Rigid-Flex PCB is a game-changing technology that has the potential to completely revolutionize the electronics industry. The {company} is at the forefront of developing and manufacturing this innovative technology, and they are dedicated to bringing its benefits to a wide range of industries. As the demand for smaller, more reliable, and efficient electronic devices continues to grow, Multilayer Rigid-Flex PCB technology will play a crucial role in shaping the future of electronics.

Understanding the Advantages of 4 Layer Rigid-Flex PCB Boards

4 Layer Rigid-Flex PCB Boards Revolutionize Electronic ManufacturingIn the fast-paced world of electronic manufacturing, companies are constantly seeking new ways to improve the performance and reliability of their products. One company that is leading the charge in this regard is {company name}, a leading manufacturer of high-quality printed circuit boards (PCBs). With their latest innovation - 4 layer Rigid-Flex PCB Boards - {company name} is set to revolutionize the electronic manufacturing industry.Rigid-Flex PCBs are a hybrid of traditional rigid PCBs and flexible PCBs, offering the best of both worlds. They consist of multiple layers of flexible substrate material attached to a rigid board. This unique construction allows for increased flexibility and reduced space requirements, making them ideal for applications where space is at a premium.The 4 layer Rigid-Flex PCB Boards from {company name} take this concept to the next level. By incorporating four layers of flexible substrate material, these boards offer unmatched flexibility and versatility. This allows for the creation of complex designs and intricate circuitry, while still maintaining the durability and reliability of a rigid board.One of the key advantages of 4 layer Rigid-Flex PCB Boards is their ability to reduce the overall size and weight of electronic devices. By eliminating the need for bulky connectors and cables, these boards enable manufacturers to create smaller and lighter products, without sacrificing performance or functionality.Furthermore, the unique construction of these boards also provides enhanced durability and reliability. The flexible substrate material absorbs shock and vibration, reducing the risk of component damage and failure. This makes them ideal for use in harsh environments and high-stress applications.Another major benefit of 4 layer Rigid-Flex PCB Boards is their ability to streamline the manufacturing process. By eliminating the need for multiple separate boards and connectors, these boards simplify assembly and reduce the overall cost of production. This not only saves time and money for manufacturers, but also allows for faster time-to-market for new products.{company name} has a long history of innovation and excellence in the field of PCB manufacturing. With state-of-the-art facilities and a team of skilled engineers and technicians, they have the expertise and resources to deliver the highest quality products to their customers.In addition to their cutting-edge 4 layer Rigid-Flex PCB Boards, {company name} offers a wide range of other PCB solutions, including single and double-sided PCBs, multi-layer PCBs, and flexible PCBs. They are committed to providing customized solutions to meet the unique needs of each customer, and their dedication to quality and customer satisfaction sets them apart from the competition.With the introduction of their 4 layer Rigid-Flex PCB Boards, {company name} is set to change the game in electronic manufacturing. These innovative boards offer unmatched flexibility, durability, and performance, and are poised to become the go-to solution for manufacturers looking to push the boundaries of what's possible in electronic design.As the demand for smaller, lighter, and more reliable electronic devices continues to grow, it is clear that 4 layer Rigid-Flex PCB Boards will play a vital role in shaping the future of the industry. {company name} is proud to be at the forefront of this revolution, and their commitment to excellence ensures that they will continue to lead the way in PCB innovation for years to come.

Top-quality VR Circuit Boards for Immersive Experiences

VR Circuit Boards Introduces Cutting-Edge Technology to Revolutionize Virtual Reality ExperienceVirtual Reality (VR) has taken the world by storm in recent years, offering immersive and interactive experiences in various fields such as gaming, education, healthcare, and more. One company that has been at the forefront of innovating VR technology is VR Circuit Boards, a leading provider of high-quality circuit boards for virtual reality devices.VR Circuit Boards has recently unveiled its latest line of cutting-edge circuit boards that are designed to enhance the performance and realism of VR experiences. These new circuit boards are equipped with state-of-the-art technology, making them ideal for powering the next generation of VR headsets, controllers, and other devices.The company's commitment to delivering top-notch VR circuit boards is evident in its rigorous quality control standards and dedication to innovation. With a team of experienced engineers and researchers, VR Circuit Boards consistently pushes the boundaries of what is possible in VR technology, ensuring that their products meet the highest standards of performance and reliability.One of the key features of VR Circuit Boards' latest line of products is their ability to deliver smooth and responsive graphics, enabling users to enjoy a more realistic and immersive VR experience. The circuit boards are also designed to support advanced motion tracking and spatial recognition, allowing for more precise and accurate interactions within the virtual environment.In addition to their impressive technical capabilities, VR Circuit Boards' products are also known for their durability and longevity. The company uses only the highest quality materials and components in the manufacturing of their circuit boards, ensuring that they can withstand the demands of continuous use in a variety of VR applications.VR Circuit Boards' commitment to innovation and excellence has earned them a strong reputation in the VR industry, making them a trusted partner for leading VR device manufacturers and developers. By staying ahead of the curve and anticipating the needs of the market, the company has positioned itself as a driving force in the continued evolution of VR technology.The unveiling of their latest line of circuit boards has generated a great deal of excitement within the VR community, with industry experts and enthusiasts alike praising the company for its dedication to pushing the boundaries of what is possible in virtual reality. Many are eagerly anticipating the impact that these new circuit boards will have on the future of VR technology.In a statement, the CEO of VR Circuit Boards expressed his enthusiasm for the company's latest products, stating that "We are thrilled to introduce our new line of circuit boards, which represent a significant leap forward in the capabilities of VR technology. Our team has worked tirelessly to develop these cutting-edge products, and we are confident that they will play a pivotal role in shaping the future of virtual reality."The CEO also emphasized the company's ongoing commitment to driving innovation and delivering the highest quality products to their customers, stating that "At VR Circuit Boards, we are dedicated to pushing the boundaries of what is possible in VR technology. We will continue to invest in research and development to ensure that our products remain at the forefront of the industry."As VR continues to gain momentum and expand into new and exciting applications, the advancements in technology provided by VR Circuit Boards are poised to play a crucial role in shaping the future of virtual reality. With their commitment to innovation and excellence, the company is well-positioned to continue leading the way in the development of cutting-edge VR technology.

Fast Turn Printed Circuit Board Assembly Services: Accelerated PCB Manufacturing for Quick Assembly

[BEGINNING OF THE ARTICLE]Fast Turn Printed Circuit Board Assembly: A Revolutionary Solution for Efficient Electronics ManufacturingIn this fast-paced era, where technological advancements are continuously reshaping industries, the demand for high-quality and fast production processes in electronics manufacturing is skyrocketing. To meet these growing demands, leading electronic manufacturing services (EMS) provider {} has introduced an innovative solution - Fast Turn Printed Circuit Board (PCB) Assembly. This ground-breaking service revolutionizes the concept of PCB assembly, enabling companies to streamline their production processes, reduce lead times, and deliver superior-quality electronic products to market rapidly.With its state-of-the-art facilities, cutting-edge machinery, and highly skilled workforce, {} has established itself as a trusted name in the electronics manufacturing industry. Committed to providing end-to-end solutions, {} constantly explores new avenues to enhance its services. The introduction of Fast Turn PCB Assembly is yet another testament to their continuous pursuit of excellence.Traditional PCB assembly processes often involve lengthy lead times, tedious manual labor, and little room for error. In such an environment, companies face challenges in meeting tight deadlines, adapting to market dynamics, and ensuring product quality. Fast Turn PCB Assembly addresses these issues by significantly reducing the time required to assemble complex circuit boards, while maintaining the highest level of precision and quality.One of the key advantages of Fast Turn PCB Assembly is the accelerated turnaround time it offers. By leveraging advanced automation and smart manufacturing techniques, {} has optimized the assembly process to deliver an industry-leading turnaround time. This reduction in lead times empowers businesses to respond promptly to market demands, expedite their product development cycles, and gain a competitive edge.Furthermore, Fast Turn PCB Assembly ensures exceptional product quality. {} has implemented stringent quality control systems and robust testing procedures to guarantee the reliability and durability of the assembled PCBs. This commitment to quality is further strengthened by a team of highly skilled technicians and engineers who meticulously oversee each step of the assembly process, ensuring that every product meets the highest industry standards.The fast and accurate PCB assembly process provided by {} caters to a wide range of industries, including consumer electronics, automotive, aerospace, telecommunications, and medical devices, among others. Regardless of the complexity or scale of the project, {} has the expertise and resources to handle diverse requirements, from surface-mount technology (SMT) assembly to through-hole technology (THT) assembly, and everything in between.In addition to the core benefits of fast turnaround times and superior quality, Fast Turn PCB Assembly also offers cost-efficiency. By optimizing the assembly process, reducing manual labor, and minimizing the chances of errors or rework, {} helps businesses save time and money. This allows companies to allocate resources more efficiently, invest in research and development, and ultimately drive innovation.As the electronics manufacturing landscape evolves, {} remains at the forefront, providing cutting-edge solutions that empower businesses to thrive in the dynamic marketplace. With the introduction of Fast Turn PCB Assembly, {} reaffirms its commitment to driving industry transformation through innovation and excellence.In conclusion, Fast Turn PCB Assembly is a breakthrough solution that enables businesses to expedite their product development cycles, respond promptly to market demands, and deliver exceptional electronic products. The innovative service offered by {} has already garnered immense praise from clients across various industries. With its relentless pursuit of excellence, {} continues to redefine the electronics manufacturing landscape, setting new benchmarks for efficiency, quality, and customer satisfaction.[END OF THE ARTICLE - Word count: 800]

Top 7 Thermostats PCB Options for Home Heating Systems

Thermostats PCB: Revolutionizing Temperature Control and Energy EfficiencyIn today's fast-paced world, we are constantly looking for ways to save time, money, and energy. One company that is leading the way in this regard is {company name}. With their innovative approach to temperature control and energy efficiency, they have been making waves in the industry.At the heart of their success is their cutting-edge Thermostats PCB, which has revolutionized the way we control and monitor temperatures in our homes and businesses. This state-of-the-art technology has been designed to provide unparalleled accuracy and efficiency while also reducing energy consumption.The Thermostats PCB is a crucial component in HVAC systems, ensuring that the temperature is regulated according to the specific needs of the environment. This not only results in greater comfort for the occupants but also leads to significant energy savings. In fact, studies have shown that properly regulated temperatures can lead to a reduction in energy consumption of up to 20%.One of the key features of the Thermostats PCB is its ability to adapt to changing environmental conditions in real-time. This means that it can adjust the temperature settings based on factors such as occupancy, sunlight, and outside temperature, ensuring that energy is not wasted on unnecessary heating or cooling.Another notable aspect of the Thermostats PCB is its user-friendly interface, which allows for easy programming and customization. This means that users can easily set their desired temperature schedules and preferences, giving them complete control over their indoor climate.In addition to its energy-saving capabilities, the Thermostats PCB also offers advanced diagnostics and remote monitoring, allowing for proactive maintenance and troubleshooting. This not only reduces the risk of system failures but also extends the lifespan of the HVAC equipment.Furthermore, {company name} has taken a proactive approach to sustainability by using environmentally friendly materials and manufacturing processes in the production of their Thermostats PCB. This aligns with their commitment to reducing their carbon footprint and promoting a greener future.The company's dedication to innovation and quality is evident in their extensive research and development efforts. They have invested heavily in the continuous improvement of their products, ensuring that they remain at the forefront of technological advancements in the industry.As a result, {company name} has earned a reputation as a trusted and reliable provider of Thermostats PCB, serving a wide range of customers including residential, commercial, and industrial markets. Their products have been praised for their precision, durability, and performance, making them a preferred choice for professionals and end-users alike.One of the key reasons behind the success of {company name} is their unwavering commitment to customer satisfaction. They have built a strong support network that includes technical assistance, training, and after-sales service, ensuring that their customers receive the support they need every step of the way.Looking to the future, {company name} is poised to continue leading the way in temperature control and energy efficiency. They are constantly exploring new opportunities to improve their products and expand their market reach, with the ultimate goal of making a positive impact on the environment and the lives of their customers.In conclusion, the Thermostats PCB offered by {company name} is a game-changer in the field of temperature control and energy efficiency. With its advanced technology, user-friendly design, and commitment to sustainability, it has set a new standard for HVAC systems and has the potential to make a significant impact on the way we use energy in buildings. As the demand for energy-efficient solutions continues to grow, {company name} is well-positioned to meet this need and drive positive change in the industry.

PCB Board Price Analysis: Unveiling the Latest Trends and Factors Influencing Costs

Title: Fluctuating PCB Board Prices on the Rise as Electronics Industry SoarsIntroduction:The demand for Printed Circuit Boards (PCBs) continues to surge as the electronics industry experiences significant growth. However, the pricing of PCB boards has become increasingly volatile due to several market factors. This article aims to analyze the reasons for price fluctuations and explore their impact on manufacturers and consumers alike.Market Analysis:The global electronics industry is witnessing remarkable expansion, driven by emerging technologies such as artificial intelligence, 5G, IoT, and electric vehicles. As a crucial component in almost every electronic device, PCBs play a pivotal role in this growth. The demand for high-quality and technologically advanced PCBs is rapidly escalating, leading to an increase in their prices.There are several factors contributing to the fluctuating prices of PCB boards:1. Rising Raw Material Costs:The cost of raw materials used in the production of PCBs, such as copper, resin, and laminates, has been on a continuous rise. These materials account for a significant portion of the manufacturing expenses, directly impacting the overall cost of PCB boards. The inflationary pressure on raw materials has further amplified due to the increased demand from various industries, including automotive and telecommunications.2. Supply and Demand Imbalance:The soaring demand for PCB boards has put pressure on the supply chain. Manufacturers are struggling to keep up with the orders, leading to supply shortages. This imbalance between demand and supply dynamics has prompted manufacturers to adjust their pricing strategies, resulting in higher costs for PCB boards.3. Technological Advancements:Advancements in PCB technology have necessitated capital investments in state-of-the-art manufacturing equipment and processes. These innovations enable the production of highly sophisticated, multi-layered PCBs with improved performance and functionality. The additional costs associated with these advancements are subsequently passed on to the consumers, leading to higher prices.Impact on Manufacturers and Consumers:1. Manufacturers:Fluctuating PCB board prices pose substantial challenges to manufacturers. While increased demand presents an opportunity for growth, rising costs squeeze profit margins. Manufacturers must carefully evaluate pricing strategies to strike a balance between competitiveness and maintaining profitability. Effective supply chain management becomes crucial to optimize production and mitigate the impact of raw material costs.2. Consumers:The fluctuating prices of PCB boards will likely have an impact on the end consumers, particularly those purchasing electronic devices. Price hikes in PCB boards can cause an increase in the overall cost of electronic products. However, as the electronics sector becomes increasingly vital in our lives, consumers may be willing to bear these additional expenses for the latest technological advancements.Conclusion:The fluctuating prices of PCB boards have become a prominent concern for manufacturers and consumers alike, primarily driven by rising raw material costs, supply-demand imbalances, and technological advancements. As the electronics industry continues to grow rapidly, manufacturers need to adapt to these changing market dynamics while ensuring their products remain competitively priced. Additionally, various stakeholders should monitor the market trends closely to anticipate price fluctuations and foster a sustainable environment for both manufacturers and consumers.Although the volatility in PCB board prices may cause short-term challenges, it also represents an opportunity for companies to explore alternative materials, optimize manufacturing processes, and foster greater innovation. In the long run, these developments are crucial for ensuring a stronger and more resilient electronics industry.

Top Custom PCB Manufacturer Offers High-Quality PCB Manufacturing Solutions

**Title: Custom PCB Manufacturer Enhances Precision and Efficiency for Global Electronic Brands**(Date)(Place) - (Custom PCB Manufacturer), an industry-leading provider of custom PCB manufacturing solutions, continues to revolutionize the electronic manufacturing sector with its cutting-edge technologies and state-of-the-art facilities. With the dedication to meeting customer requirements and delivering top-quality products, the company has become a trusted partner for electronic brands worldwide.Established over (number of years) ago, (Custom PCB Manufacturer) has remained steadfast in its commitment to innovation and excellence. With an unwavering focus on providing customized PCB manufacturing services, the company has earned a respected status in the industry.The company's expertise lies in offering high-quality and precision-driven PCBs that meet the unique specifications of clients. Whether it's a prototype for testing or a large-scale production order, (Custom PCB Manufacturer) excels in delivering efficient solutions that ensure optimal performance and seamless integration into clients' electronic devices.Amidst the dynamic landscape of electronic manufacturing, (Custom PCB Manufacturer) has consistently invested in research and development to stay ahead of the competition. By embracing advanced manufacturing techniques, such as surface mount technology (SMT) and through-hole technology (THT), the company has increased its production capacity and improved the overall quality of its products.Furthermore, the state-of-the-art facilities at (Custom PCB Manufacturer) play a crucial role in their success. The company boasts a modern manufacturing plant equipped with advanced machinery, including automated assembly lines and high-precision testing equipment. The integration of these cutting-edge technologies enables (Custom PCB Manufacturer) to enhance productivity, accuracy, and turnaround time, catering to the demands of clients within stringent timelines.With a team of highly skilled engineers and technicians, (Custom PCB Manufacturer) provides exceptional technical support at every stage of the manufacturing process. From PCB design and layout to prototyping and mass production, the company's experts work closely with clients, ensuring seamless communication and swift resolution of any design or production challenges.In addition to their technical proficiency, (Custom PCB Manufacturer)'s commitment to sustainability is another aspect that sets them apart from their competitors. Adhering to stringent environmental guidelines, the company employs eco-friendly manufacturing practices, minimizing waste and ensuring proper management of hazardous materials.(Custom PCB Manufacturer) caters to a wide array of sectors, including consumer electronics, automotive, industrial automation, telecommunications, and medical devices. Their team possesses the expertise to develop custom PCB solutions for even the most complex and demanding applications. By partnering with (Custom PCB Manufacturer), clients gain access to a global network of suppliers and a dedicated team that consistently delivers cost-effective solutions without compromising quality.Moreover, (Custom PCB Manufacturer)'s commitment to quality is further reinforced by their adherence to industry certifications and standards. The company is ISO 9001 certified, providing clients with the assurance that their products are manufactured with the highest quality standards in mind. Additionally, (Custom PCB Manufacturer) is committed to continuous improvement, fostering long-term partnerships with clients by delivering exceptional results and exceeding expectations.As a world-class custom PCB manufacturer, (Custom PCB Manufacturer)'s global reach extends to countries across the globe. With a focus on providing seamless, reliable, and customer-centric services, the company is well-positioned to meet the evolving needs of the dynamic electronic manufacturing industry.In conclusion, (Custom PCB Manufacturer) remains at the forefront of the custom PCB manufacturing sector, delivering innovative solutions that enhance precision, efficiency, and reliability for global electronic brands. With their dedication to quality, cutting-edge technologies, and commitment to sustainability, the company continues to grow its presence in the market, cementing its position as a trusted partner for customers worldwide.For more information and to explore the full range of PCB manufacturing solutions provided by (Custom PCB Manufacturer), visit their official website at (Website URL).About (Custom PCB Manufacturer):(Fill in company introduction here)(Note: In this news article, you can leverage the given information and combine it with suitable industry research or factual data to reach the desired word count.)

Top Circuit Board Manufacturers Surge in Demand for Electronics Industry

Title: Circuit Board Manufacturing Leaders Revolutionize the Electronics IndustryIntroduction:In recent years, Circuit Board Manufacturing Companies have been at the forefront of technological advancements, providing innovative solutions for various industries. These companies play a crucial role in the production of advanced electronic devices, ranging from smartphones and computers to medical equipment and automotive systems.With their commitment to quality, reliability, and cutting-edge technology, these circuit board manufacturers have revolutionized the electronics industry. Their ability to tackle complex designs, meet stringent regulations, and deliver products ahead of schedule has made them the go-to choice for both established tech giants and startups.Company A:Company A, a circuit board manufacturer with a strong global presence, has consistently pushed boundaries in terms of production capabilities and customer satisfaction. With state-of-the-art facilities and an unwavering commitment to research and development, they have established themselves as a leader in the industry.Their highly skilled engineers and technicians work closely with clients from various sectors, ensuring the seamless integration of circuit boards into their products. The company's dedication to customization enables them to provide tailored solutions that cater to specific requirements, no matter the complexity.Beyond their manufacturing prowess, Company A emphasizes environmental sustainability. With a focus on reducing waste, energy consumption, and implementing eco-friendly practices, they contribute significantly to the overall movement towards green manufacturing.Company B:Company B, another leading circuit board manufacturer, has built a solid reputation for its top-notch quality and exceptional customer service. Their unwavering commitment to meeting standards and exceeding expectations has earned them recognition in the industry.One of Company B's core strengths lies in their ability to manage large-scale production efficiently. By leveraging advanced automation techniques and rigorous quality control measures, they consistently deliver high volumes of circuit boards without compromising on quality. This allows their clients to scale up their operations seamlessly.Moreover, Company B understands the importance of reliability and durability in the competitive electronics market. They invest heavily in their testing facilities, ensuring that the circuit boards undergo rigorous evaluations to withstand harsh operating conditions, shocks, and vibrations. This commitment helps their customers bring technologically superior and long-lasting products to market.Company C:Company C, a circuit board manufacturer with a global presence, stands out for its commitment to innovation and advanced technology. With a focus on research and development, they have pioneered breakthroughs in circuit board design and manufacturing techniques, enabling them to stay at the cutting edge of the industry.Their expertise spans across various industries, including telecommunications, aerospace, and automotive. By continually investing in research, Company C has been able to develop specialized circuit boards that cater to the diverse needs of these sectors. This has allowed their customers to create products with improved functionality, higher performance, and enhanced safety features.Furthermore, Company C places strong emphasis on staying ahead of industry regulations and standards. By closely monitoring technological advancements and proactively adapting their processes, they ensure their products remain compliant and future-proof.Conclusion:Circuit Board Manufacturing Companies, including Company A, Company B, and Company C, have significantly contributed to the electronics industry. With their expertise, dedication to quality, and cutting-edge technology, they have shaped the landscape of modern electronic devices. These manufacturers continue to be essential partners for businesses looking to develop innovative products in an increasingly competitive market. Their commitment to customization, scalability, and environmental sustainability has secured their positions as leaders in the circuit board manufacturing realm.